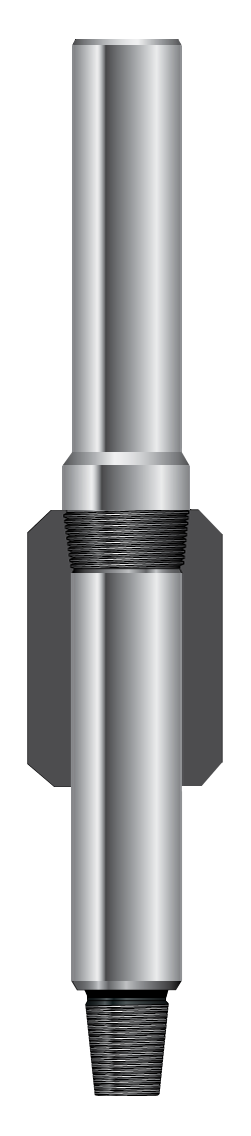

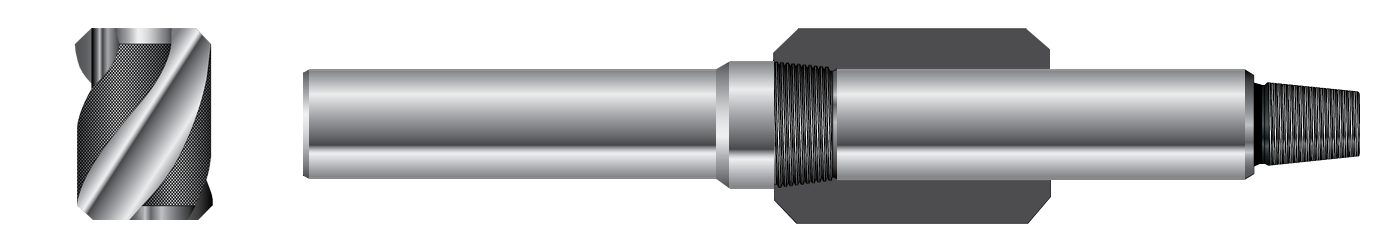

Our sleeve stabilizers are the product of simple design coupled with engineered technology. We understand the need to swiftly change out a sleeve on the rig floor which is why our sleeve and mandrel design is virtually foolproof. Our one-piece mandrel is manufactured from high strength 4145 heat treated alloy with ample tong space for connection recuts.

Easily interchanged with other brands, our sleeve and mandrel design is long-wearing and extremely economical. When they wear out, they can simply be thrown away - a must for remote areas where there is limited access to a field shop and inventory must be kept light.

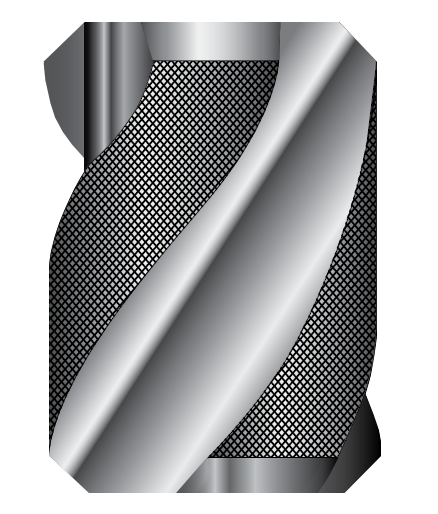

Due to our hardfacing abilities, our sleeves can be stocked in the same sizes to meet different formation demands while being interchangeable to fit the same mandrel.

For more information about hardfacing, click here.

Using client supplied drawings and specifications, Drilling Tools International is able to manufacture any type of 4145 HT steel sleeve stabilizer or nonmagnetic type sleeve. Utilizing our in-house engineering team and the latest 3D modeling software, we are also able to assist with the design process. Coupled with the latest CNC milling equipment we are able to produce any blade configuration or dimensional requirement a client might need. With a large inventory of steel and non magnetic heavy wall tubing and custom forgings, we are able to deliver custom sleeves with relatively short lead times. This ability coupled with the application or our latest hardfacing technology assures optimal run time and durability.

| Sleeve Series/Size | Hole Size or Blade O.D. Range (in) | Sleeve Body Diameter (in) | Sleeve I.D. (in) | Sleeve Length (in) | Blade Width (in) | Minimum Crown Length (in) | Maximum Sleeve Weight (lbs) |

|---|---|---|---|---|---|---|---|

| 475 | 6 1/4 - 6 3/4 | 5 3/4 | 4 3/4 | 14 | 2 | 12.2 | 43 |

| 625 | 8 3/8 - 9 7/8 | 7 1/2 | 6 1/4 | 14 | 2 1/2 | 11.1 | 84 |

| 775 | 8 7/8 - 12 1/4 | 9 1/4 | 7 3/4 | 18 | 3 | 14.6 | 162 |

| 775 | 10 5/8 - 17 1/2 | 10 | 7 3/4 | 18 | 3 | 11.1 | 294 |

| 963 | 12 1/4 - 17 1/2 | 11 | 9 5/8 | 18 | 3 1/2 | 11.9 | 253 |

| Mandrel Series | Maximum Fishing Neck Diameter (in) |

Mandrel Upset Diameter (in) | Sleeve End Diameter (in) | Fishing Neck Length (in) | Sleeve End Length (in) | Total Overall Length (in) | Bore I.D. | Maximum Mandrel Weight (lbs) |

|

|---|---|---|---|---|---|---|---|---|---|

| Near Bit | String | ||||||||

| 47 | 4 3/4 - 5 | 5 1/8 - 5 3/4 | 4 3/4 | 23 | 32 | 62 | 1 1/2 | 2 1/4 | 302 |

| 62 | 6 1/2 - 7 | 7 1/2 | 6 1/4 | 23 | 32 | 62 | 2 1/4 | 2 13/16 | 500 |

| 77 | 8 1/4 | 9 1/4 | 7 3/4 | 27 | 37 | 71 | 2 13/16 | 2 13/16 | 893 |

| 96 | 10 | 11 | 9 5/8 | 27 | 37 | 71 | 2 13/16 | 2 13/16 | 1400 |

| Series | 41 | 47 | 62 | 65 | 77 | 85 | 96 |

|---|---|---|---|---|---|---|---|

| Make-up Torque (ft-lbs) | 2000-2500 | 2000-2500 | 4500-5500 | 5000-6000 | 7000-8000 | 10000-12000 | 10000-12000 |

Drilling Tools International, Copyright 2026 ©