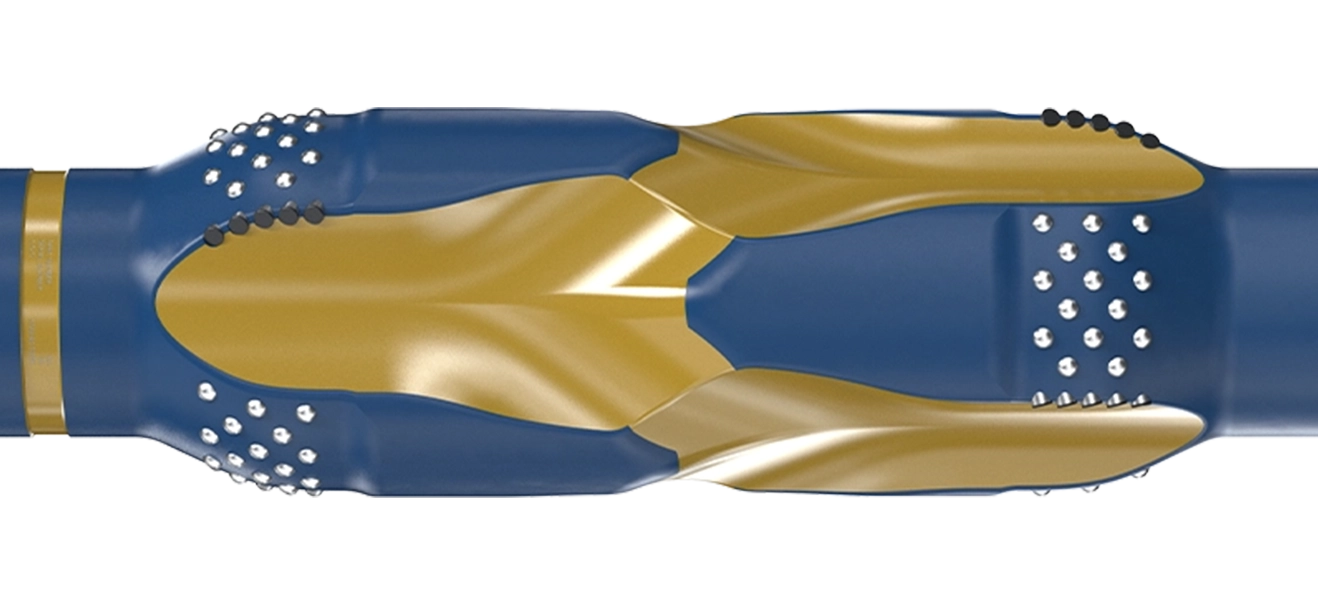

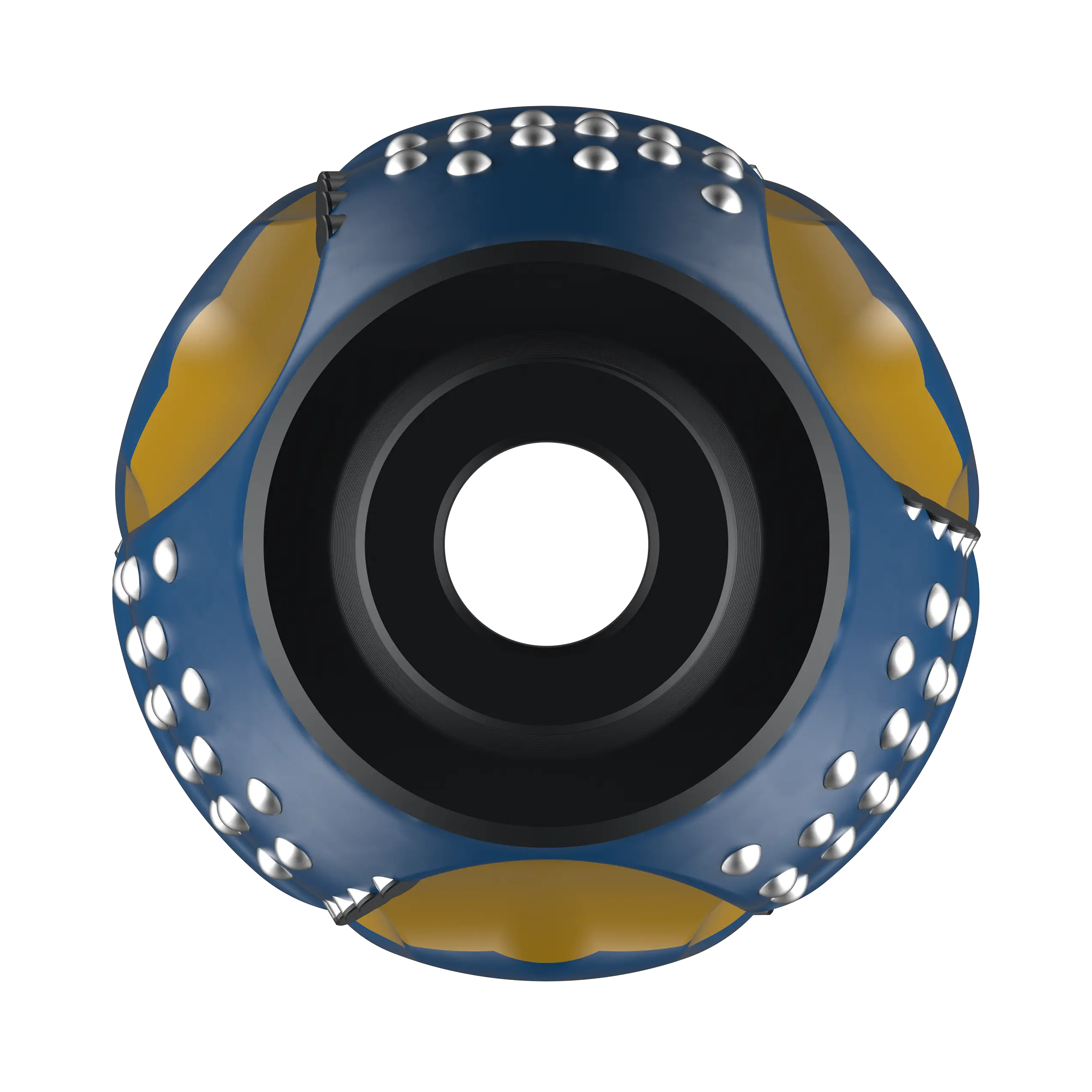

Ream when you need to, not because you can. The Dome hybrid reamer, a stabilizer while drilling, a reamer when you need one. This innovative design has a similar profile to the FixedBlade stabilizer but offers an overall longer blade length to support a unique three-stage taper with different cutter types. The 3-stage taper is created to ensure a gradual cutting action starting at 14 degrees at the bottom, 5 degrees in the middle, and 2 degrees as a transition zone to the hardfacing.

The pin-side has numerous TCIs spread out over the 3-stages with flat PDC cutters positioned near the hardfacing for extra protection. The box-side is set up similarly but also integrates different stud PDC cutters for extra backreaming capabilities.

The Dome hybrid reamer is the ideal tool to position as the top stabilizer for extra protection for the BHA, ensure backreaming capabilities, without intervening with any weight on bit or torque issues.

Passive reaming capability up-and-down

The 3-stage taper is created to ensure a gradual cutting action starting at 14 degrees at the bottom, 5 degrees in the middle, and 2 degrees as a transition zone to the hardfacing.

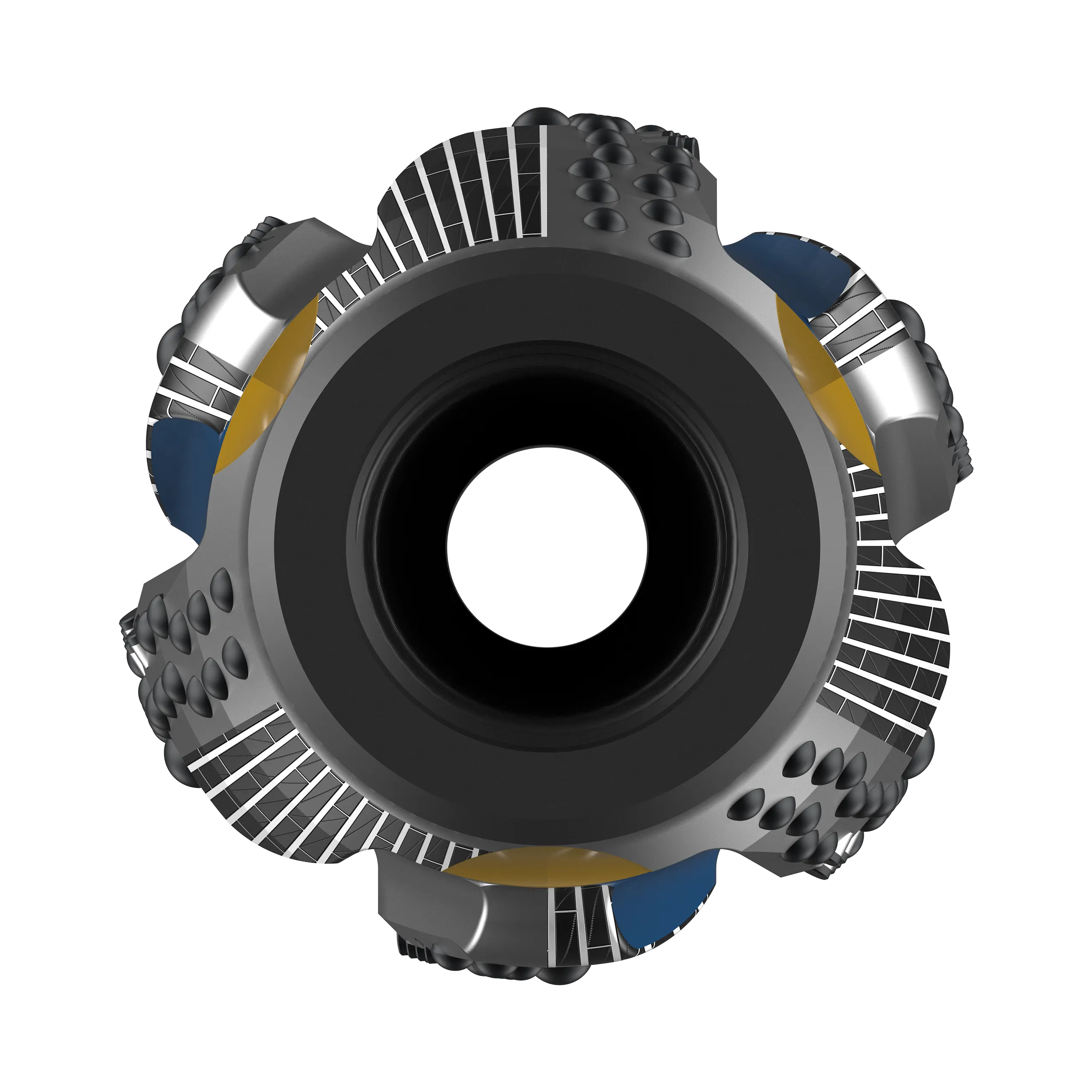

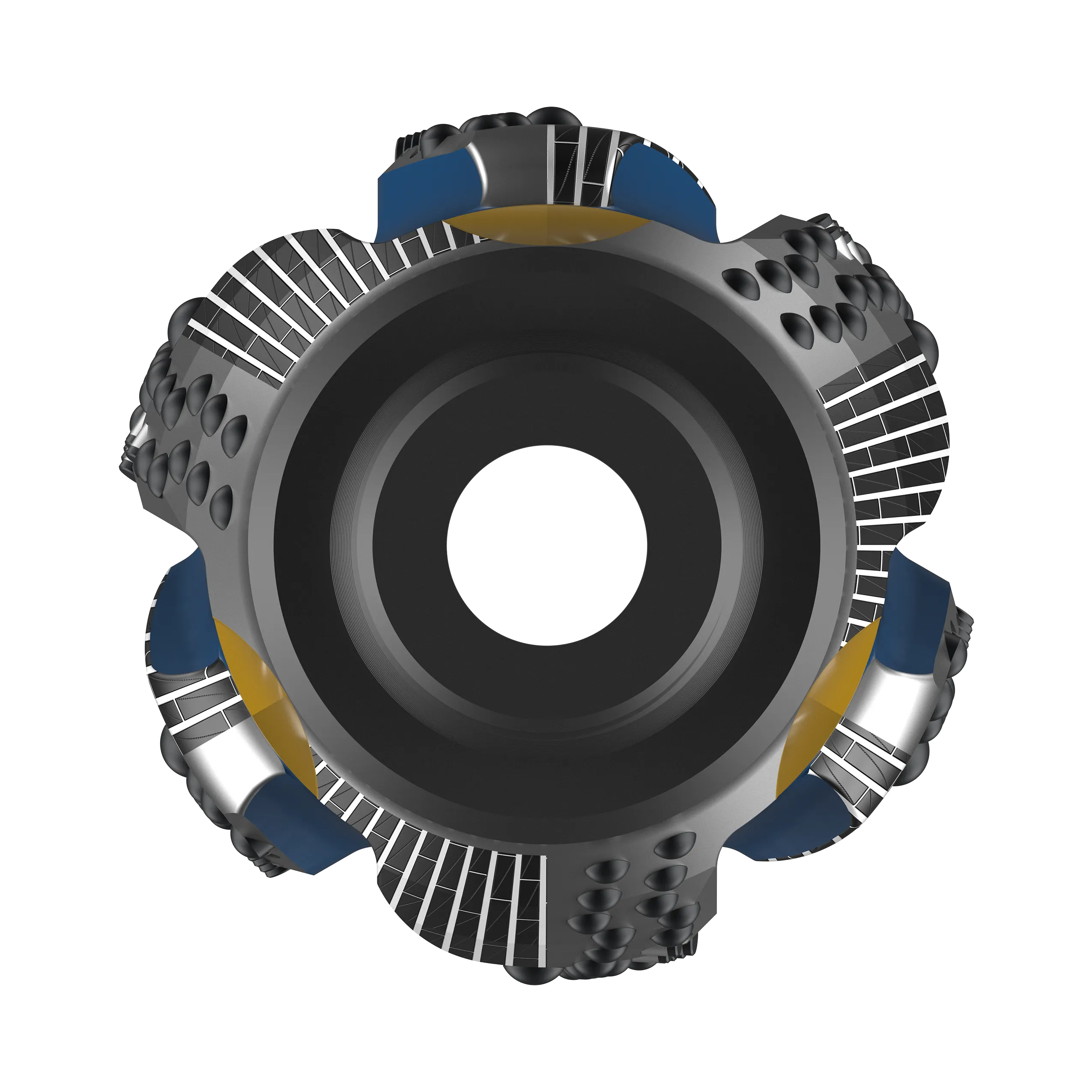

The FixedBlade reamer is engineered to achieve optimal borehole gauge while effectively minimizing wellbore imperfections, including borehole tortuosity. This is achieved through the controlled elongation of micro doglegs and borehole spiral patterns during the drilling process.

To maximize its efficiency, the FixedBlade reamer should be positioned high-up in the drill string and operated under tension.

Bi-directional reaming capabilities

The FixedBlade reamer boasts an advanced design featuring optimized hydrodynamics, enabling enhanced transportation of cuttings surrounding the stabilizers.

The cutter configuration allows for forward and back-reaming capabilities.

| Hole-Size | Gauge-Range | Length (m) | Weight (kg) | ID | Fishing Neck Diameter |

Surface Area (in2) |

Connection |

|---|---|---|---|---|---|---|---|

| 6″ series | 5 3/4″ – 6 1/4″ | 2.00 | 180 | 2″ | 4 3/4″ | 100 | NC38 |

| 8″ series | 8″ – 8 1/2″ | 2.20 | 360 | 2 1/4″ | 6 3/4″ | 220 | 4 1/2″ IF |

| 12″ series | 12″ – 12 1/4″ | 2.40 | 660 | 2 13/16″ | 8 1/4″ | 240 | 6 5/8″ Reg |

| 17″ series | 14 3/4″ – 17 1/4″ | 2.60 | 1200 | 3″ | 9 1/2″ | 340 | 7 5/8″ Reg |