To meet a variety of the most demanding drilling conditions, we offer hardfacings in five different options for our stabilizer blades. We are constantly working to develop improvements on wear characteristics and matrix hardness. Our extensive research has increased reliability in bonding. Each hardmetal is tailored to your specific needs and our expert application ensures exceptional resistance to wear and tear, prolonging the life of your tool.

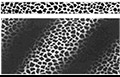

Geothermal hardfacing utilizes tungsten carbide bricks, brazed to the stabilizer blade and surrounded by tungsten impregnated composite rod.

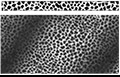

A hardfacing method that applies the maximum amount of premium tungsten carbide on any wear surface. It can be applied in varied thickness and uses tungsten carbide inserts to maximize abrasive and impact durability.

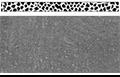

Most common hardfacing technique that utilizes crushed tungsten in a nickel bronze matrix for soft to medium drilling applications.

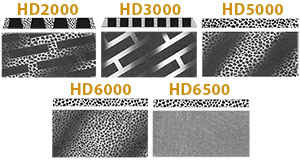

A premier hardfacing which suspends fine tungsten carbide pellets or crushed material in a hard, ferrous matrix. The matrix attains a hardness of approximately 45 HRC and is completely saturated with carbide. It is typically used with non-magnetic stabilizers due to lower application temperature.

This slag-free material features a high density of hard-cast tungsten carbide particles evenly distributed in a nickel allow matrix. It offers exceptional resistance to abrasive and erosive particles with moderate impact and is applicable with all body materials. This matrix attains a hardness of approximately 55 HRC.

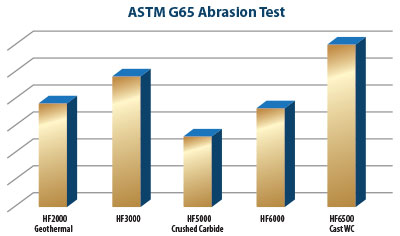

Abrasion testing completed per ASTM G65 – 16 using the dry sand/rubber wheel test method and quantitative values determined from adjusted weight loss.

Drilling Tools International, Copyright 2026 ©