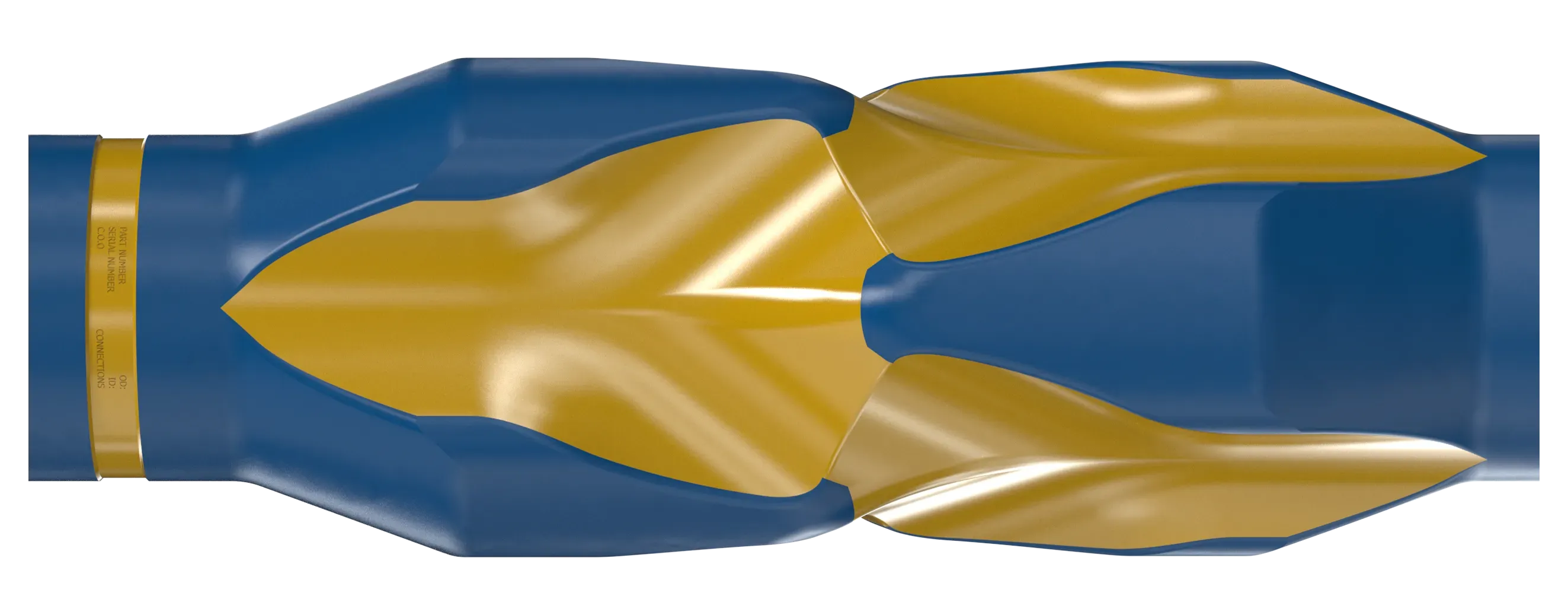

The FixedBlade stabilizer is ideal for all drilling locations in vertical or deviated wells where drilling gauges are clearly established. With its enhanced hydrodynamic design, created using industry standard computational fluid dynamic modelling, the FixedBlade stabilizer serves to reduce balling whilst increasing overall drilling efficiency.

The unique profile and blade orientation improve BHA stabilization by reducing torque, drag, and vibration – all key causes of borehole enlargement and subsequent BHA component failure.

The FixedBlade stabilizer is a direct replacement to conventional drilling stabilizers and can be used in any drilling application.

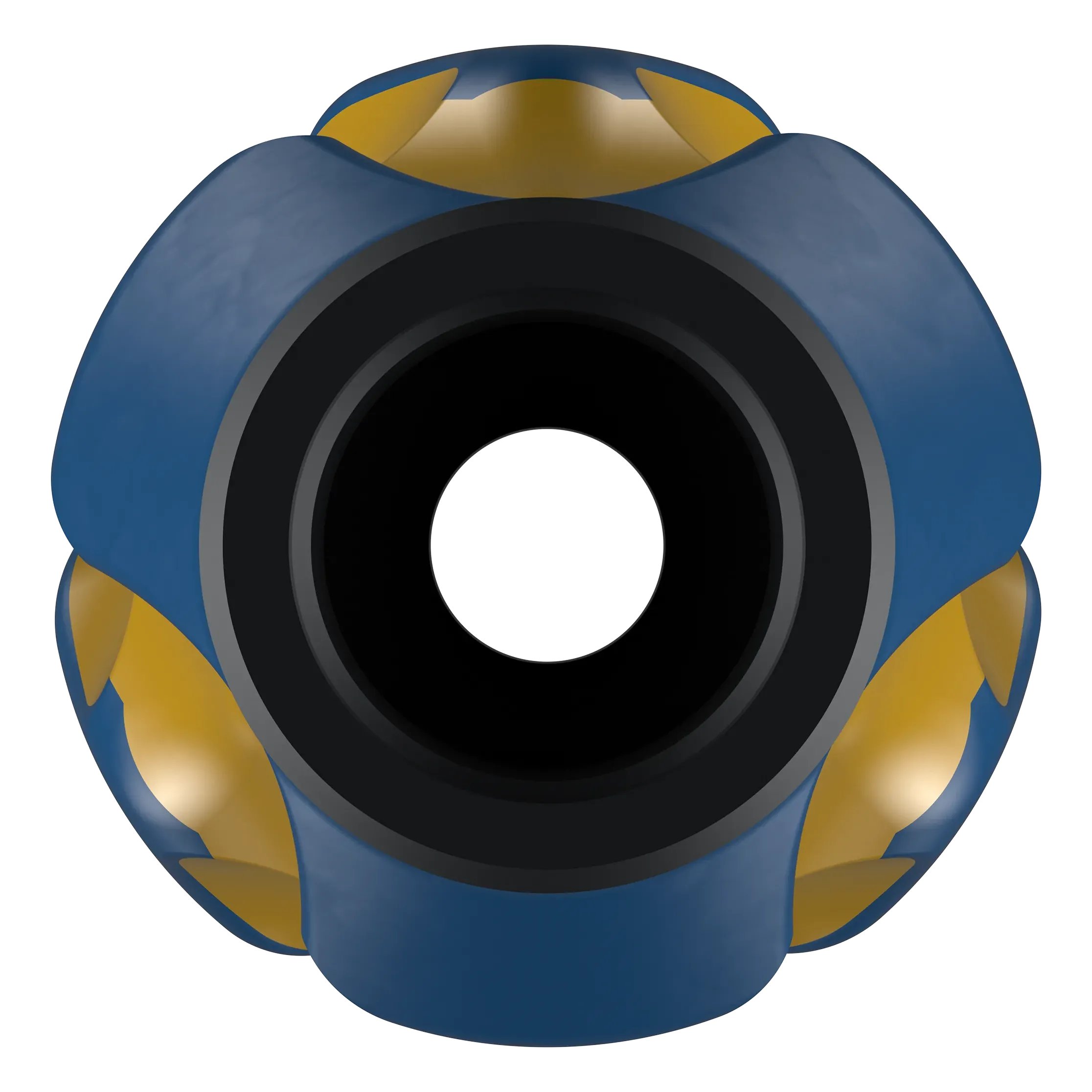

Blade geometry and configuration:

The six blade orientation and smooth dome profile provide three key benefits

Hydrodynamic Design:

The FixedBlade stabilizer offers a simple yet innovative solution that enhances drilling performance, prevents downhole failures, and makes tripping easier.

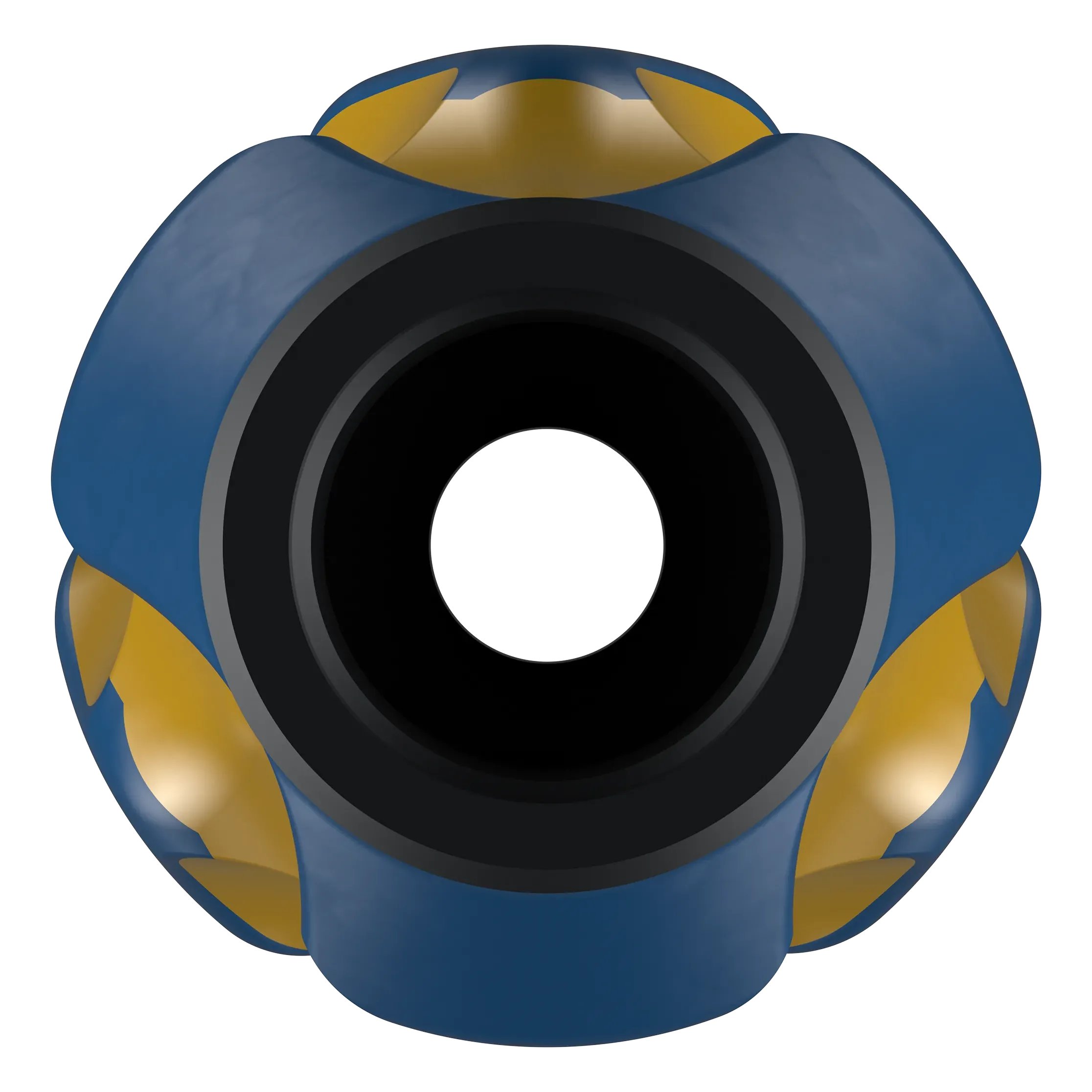

The FixedBlade® Nearbit stabilizer was designed to address the known shortcomings of the conventional spiral blade nearbit stabilizer. The simple yet innovative solution enhances drilling performance by maximizing stability at the bit and minimizing bit whirl.

The Nearbit stabilizer is ideal for rotary BHA's when used in conjunction with the FixedBlade string stabilizer and/or a Dome Hybrid Reamer.

The FixedBlade® Nearbit stabilizer offers a simple yet innovative solution that enhances drilling performance, prevents downhole failures and makes tripping easier.

| Blade Diameter |

Length (m/in) |

Weight (kg/lbs) |

ID | Fishing Neck Diameter |

Surface Area (in2) |

Connection | TFA% |

|---|---|---|---|---|---|---|---|

| 5 7/8″ | 1.8 / 70 | 121 / 266 | 2.125″ | 4.75″ | 100 | NC38 | 31 |

| 8 1/4″ | 1.6 / 62 | 230 / 507 | 2.813″ | 6.75″ | 120 | NC50 & 4 1/2″ Reg | 31 |

| 8 3/8″ | 1.9 / 74 | 272 / 599 | 2.813″ | 6.75″ | 120 | NC50 & 4 1/2″ Reg | 30 |

| 9 13/16″ | 1.7 / 66 | 331 / 729 | 2.813″ | 8″ | 160 | 6 5/8″ Reg | 41 |

| 12 1/8″ | 1.7 / 66 | 433 / 954 | 2.813″ | 8.25″ | 270 | 6 5/8″ Reg | 32 |

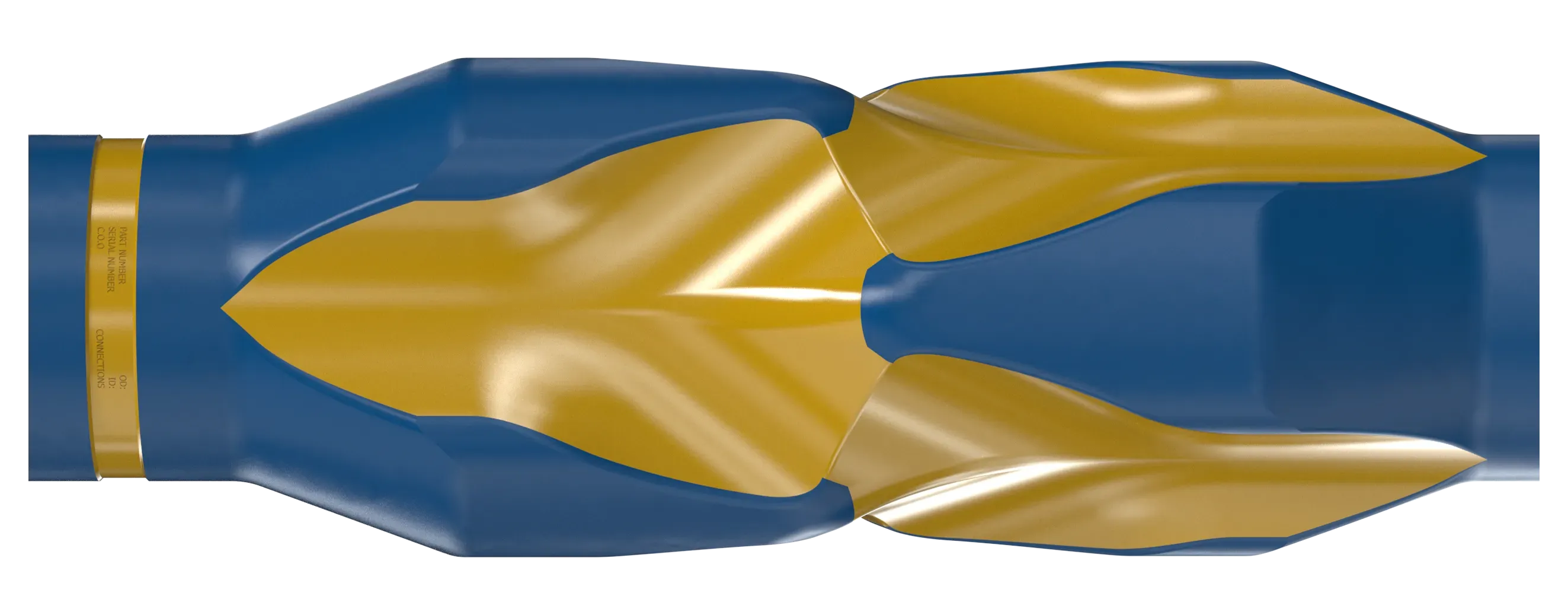

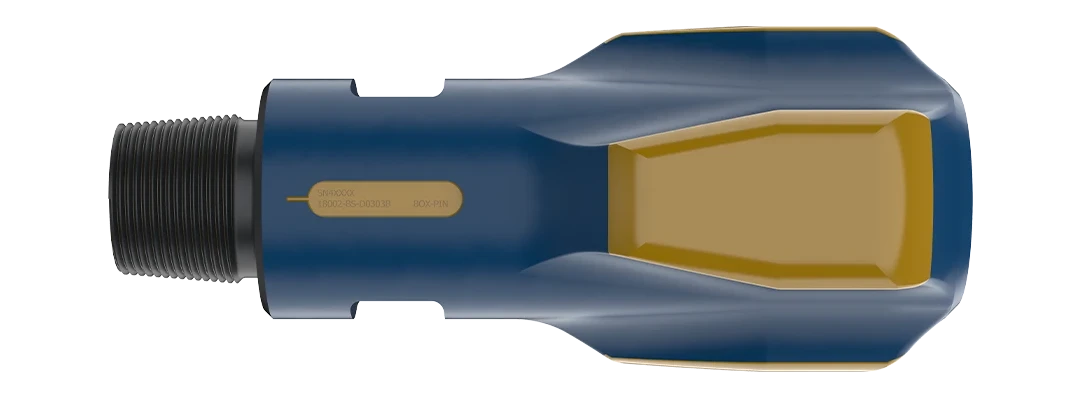

The FixedBlade® Bitbox stabilizer directional drilling tool was designed to address the known shortcomings of drill bit stabilization. Utilizing the FixedBlade hydrodynamic design, enables enhanced fluid displacement and near bit stabilization without compromising steerability or torque levels.

The FixedBlade® Bitbox stabilizer was designed to replace the need for static motor sleeve stabilization, improving weight transfer and tool face control when slide drilling. This design bitbox is also suitable for BHA's with point-the-bit RSS, allowing the use of short-gauge bits without compromising directional performance and hole quality. It could also help maintain angle in vertical or tangent sections when used with point- or push-the-bit RSS.

The FixedBlade® Bitbox stabilizer is placed directly above the bit and has three points of contact with the wellbore. It is equally suited for use on either mud motor or RSS applications. The Bitbox stabilizer improves bit stability, minimizing whirl and spiraling.

On steerable motors the rotating bit box stab replaces the static bearing-housing motor sleeve, reducing friction and improving weight transfer when slide drilling. That minimizes the risk of hanging up, motor stalling, and subsequent loss of tool face.

When running with point-the-bit RSS, it allows using regular drill bits with short gauge without compromising hole quality. Similar to other FixedBlade® stabilizers, it has low-friction dome-shaped blades. The Bitbox stabilizer also has superior hydrodynamic properties providing resistance to balling up and packing off.

| Hole-Size | Gauge-Range | Length (m) | Weight (kg) | ID | Fishing Neck Diameter |

Surface Area (in2) |

Connection |

|---|---|---|---|---|---|---|---|

| 8 1/2″ | 7 7/8″ – 8 1/2″ | 0.36 | 63 | 2 1/4″ | 6 3/4″ | 75 | 4 1/2″ IF |

| 12 1/4″ | 11 7/8″ – 12 1/4″ | 90 | 90 | 2 13/16″ | 8 1/4″ | 85 | 6 5/8″ Reg |