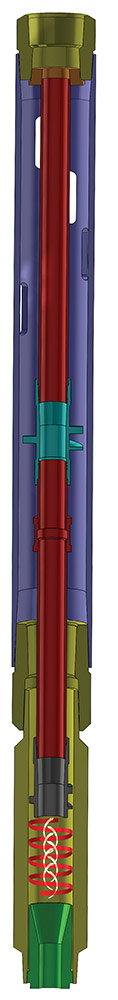

Desander

Downhole Desander

Downhole Sand and Gas Mitigation Tools

We offer a product line of multiphase desander equipment for downhole

sand and gas mitigation for rod pump applications. Our multiphase separator is

designed to meet the harsh conditions of the downhole environment.

Incorporation of our desander will help to reduce sand content in the produced

fluids before reaching the pump, resulting in extended pump life. The separation

methods are field proven, and each system is designed to meet or exceed

applicable standards.

Design features

- Primary (Sand) spiral to separate sand and solids

- Secondary (Gas) spiral to assist in gas breakout and separation

-

30' diptube allows sufficient distance for gravity separation of free gas as fluid

travels through the desander

-

Stainless steel diptube offers high resistance to corrosion, ensuring long

operational life of equipment

-

Lower bottom sub is offered in two options:

– Heavy wall is machined from 4140 steel with a 3/4" wall thickness for

extended erosion life

– Light wall is machined from 4140 steel with a 5/16" wall thickness

– Both subs utilize a machine flat along their axis to ensure the mud anchor is

not severed from the bottom of the desander due to erosion at the end of

their useful life

-

Screen wrapped slotted section is optional

– Slotted section is typically screen wrapped to prevent large foreign material

from entering desander and plugging pump

Benefits

| Standard API connections |

| Centrifugal force acts on spiral for particle and gas separation |

| Reduce chances of premature pump failure due to erosion/abrasion with 35% thicker wall |

| All steel construction |

| Suitable for any Bottom Hole Temperature/Pressure |

| Multi configuration bottom sub application per user needs |

| Efficient separation of free gas |

| Production/Completion Engineering 24/7 Support |

Applications

| Downhole pumps (e.g., ESP, Traditional Sucker Rod) |

| 15-370 bbl/day |

Additional Information